Revolutionizing Seawater Systems for the 21st Century

What problem was PHIBER Systems designed to resolve?

PHIBER’s genesis is a common story of inboard engines overheating due to scale and corrosion. When a marine engine is shut down, the raw water cooling stops, trapping seawater inside heat exchangers and engine blocks. Because the residual engine heat has nowhere to go but into the seawater, it raises the temperature to the point that the minerals, biologics and other contaminants in the seawater precipitate out, and adhere to surfaces. With repeated use, this hard scale buildup inevitably robs the engine of its ability to remove heat, causing higher operating temperatures and risking damage to the engine. Additionally, seawater promotes corrosion and other types of biofouling as it sits. The cost for heat exchanger repair is astronomical! We know, it was that very event on a pair of inboard diesels that sparked the invention.

PHIBER Systems address these issues by flushing the engine with freshwater at the optimal time, right before shutdown, pickling the heat exchangers and engine blocks with freshwater instead of seawater. This preventative maintenance removes the opportunity for harmful scale buildup in the heat exchangers and mitigates biofouling and corrosion. This extends the service life of critical systems and keeping vessels on the water longer.

Who is the target market?

If a marine system uses raw water for cooling, it’s on our radar. With that said, we are having a lot of fun and success with a wide range of boaters, from center consoles to the sportfish guys and gals. Ultimately, we are targeting the entire yachting and cruising communities, commercial vessels, and even institutional customers like merchant marine, Coast Guard, and more. Our immediate focus is to develop a skilled dealer/installer network.

Who is currently using PHIBER Systems? What is their feedback?

Over the last 4 years of development, we have outfit a wide range of marine applications and vessels using PHIBER Systems from catamarans to sportfish, inboard and outboards. Many of these early adopters were equipped with the prototype or developmental versions of the system during our testing and data-collection phase of product development. We started actively selling the current systems in June 2024. Regardless if it was an early system or a brand new one, the feedback has been amazing.

“Covert Mission” is an award-winning 58’ Viking Yacht with twin MAN engines. She received her PHIBER Systems in July 2024, and just arrived back into Stuart, Florida from Cape May, New Jersey where she fished several tournaments this summer including the White Marlin Open and Mid Atlantic. We couldn’t ask for a better operator/owner Jim McCarthy who not only is an excellent fisherman but also a professional engineer. His system was installed in July, and within 24 hours of being completed, he ran Covert Mission the 100 miles to the Canyons for summer Marlin fishing. At the end of every trip, his engines are flushed before the first person can get off the boat. He is really satisfied and referring friends. Our first install was aboard

Senergy, a 480 Voyage catamaran (which also happens to be PHIBER Systems inventor’s home) was back in 2021. That boat currently has over 2000 hours on its twin Yanmar engines.

What kind of boats are PHIBER Systems being used on? How has it changed the boat building process?

To date, we are still in retrofits (small detail, we just launched sales in summer 2024). PHIBER Systems are installed on multiple brands and types of vessels. Regulator, Voyage, Hatteras, Viking, Orion, and many more. Systems flushed include MTU, MAN, Yanmar, Caterpillar, Cummins, Yamaha and Mercury. There were about a dozen initial boats ranging from 21’ Triumph with a single Honda 200 outboard engine to the most recent, a 2021 Viking 58’ with twin MTUs. This Viking, “Ambush”, belongs to our first dealer in Panama, and is a big leap forward for us because the twin diesels warranty was recertified with the PHIBER System! We know this will support our market expansion as we work towards industry adoption.

Which builders/installers are using PHIBER Systems?

We are currently onboarding several OEM builders and installers to offer our system as a lineitem option on their boat build sheets and list of services. I’d love to disclose the manufacturers but until the ink is dry, NDA it is!

Everyone loves the simplicity, minimal foot print, as well as the many safety checks ensuring the other operating systems are unaffected. We love the reaction “you figured it out for inboards?” and “it only takes 30 seconds?” from the outboard community.

Why do you think no one has designed a product like PHIBER before?

This is a great question. Raw water networks aboard boats haven’t had a significant improvement since the sea-strainer was developed back in the 1940s. It has taken a fair amount of time, thought, money, and willingness to fail along this PHIBER Journey. But, the marine industry is waking up to the disruption for good that PHIBER represents. We are optimistic that the standard accepted practices and culture will move in a positive direction with PHIBER methods and that everyone can find benefit in our solution.

What obstacles arose while designing PHIBER through the R&D process?

Oh gosh, you name it. Have you ever seen a solenoid valve melt? Created intuitive firmware with software engineers who have never laid foot on a boat? Played Tetris with raw water networks that are 50 years old? The biggest challenges were ensuring potable water is always protected and that engines would always have access to waterflow whether our system was working or not. The Manifold design is so clever, and operates using only physics dare we say, it is “perfect”?

What impact do you see PHIBER having on the industry?

PHIBER’s goal is this: Get rid of the garden hose and simplify preventative flushing maintenance for all raw water networks. It takes the very laborious, risky, and often ignored practice of freshwater flushing and turns it into a “decision point” through push-button functionality. We ultimately intend to set a new standard of design for all boats, streamlining routine preventative maintenance processes. It is also amazing to be recognized as a push button way for boaters to be eco-friendly with far less water used and material wasted. PHIBER will have significant positive impact the marine industry!

What plans do you have for the future of this design?

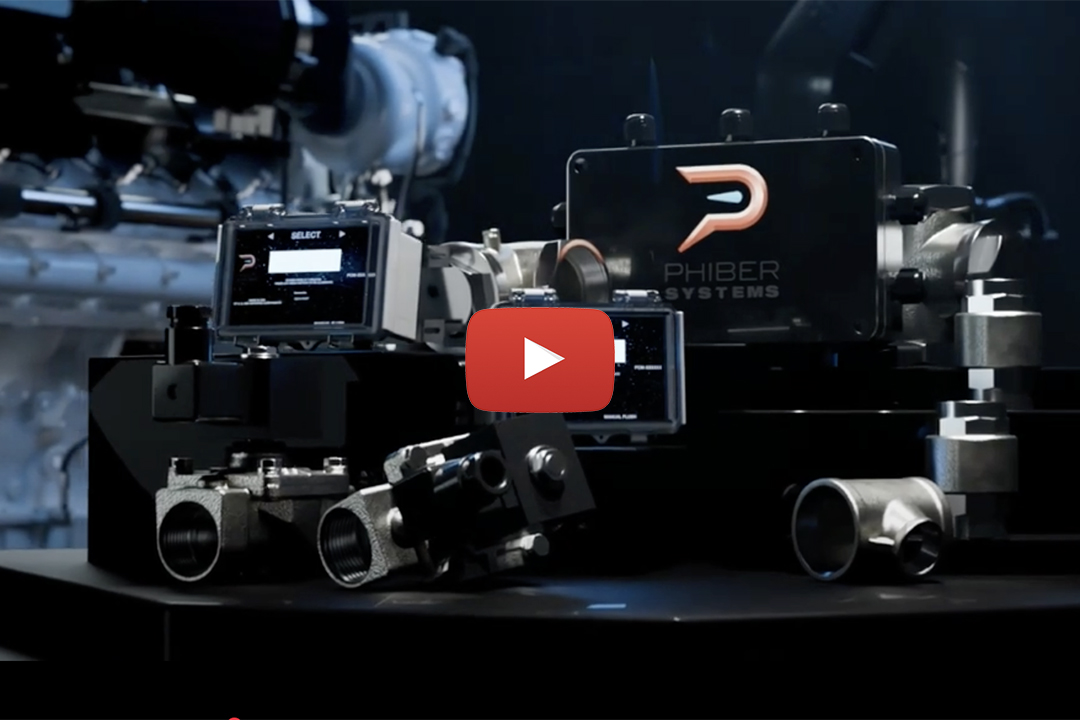

There is a lot to cover with this question. As you can imagine, we have a few things in the works. To start, we will be rolling out our Intelligent Sequencer in 2025 to serve the outboard industry. Unlike every other system on the market, our PHIBER System will flush up to SIX networks… lightning fast, with minimal water requirements, and at the push of a button! Other innovations include NMEA2000 compatibility for interfacing with multi-function displays, blue tooth enabled capabilities, manifold 2.0, and a few gadgets that the marine industry desperately needs. The advent of PHIBER has unlocked an entirely new path for both problem solving and product development and we are geographically located with access to water and marinas!

What plans are in place for the future of PHIBER Systems as a company? You’ve come up with some creative products… what’s next?

We do have a sizeable sales goal for 2025 based on initial launch requests which will test our manufacturing capabilities. We’d love to reach a meaningful adoption rate within the next 5 years to affect industry change. PHIBER Systems has been approached by various industries to use the application in so many ways, its wild! As far as the marine industry, we would love to have a fun retail brand. Can you imagine a line of pickles, napkins or spirits? Opportunities abound!

Finally, creative marketing, does this play a role in your success?

Let’s face it, flushing raw water cooling systems isn’t sexy or funny. Actually, it’s a source of pain for most boat owners, builders, etc. But its also boring. Can you imagine if we named the company “Raw Water Flushing System Co.”? The name PHIBER was born from the “human experience”. Having fiber in our diet keeps things regular and moving in our plumbing networks. The same applies for our boats… PHIBER keeps things “regular” in the engine rooms. (In case anyone is wondering, it stands for “Pressurized Hydro Injection for Brine Evacuation Remediation”). One could surmise we have more fun than we should for a startup company taking on the industry after spending over half a million dollars and cutting into the biggest operation system and price tag for any boater. But also, funny is funny, and that’s likely why we all gravitate towards this amazing marine industry where its ok to have a great time.